Making a push-fit plastic joint

Making a push-fit plastic joint is one of the simplest techniques for joining plumbing supply pipes in your home. Plastic pipes are now commonly used for  both water supply, and heating pipes. Because they are joined using push-fit joints, makes them a popular option for the DIY market. One type of plastic pipe is shown below – there are others and so always check manufacturer’s guidelines on approved methods of connection and how joints may be disconnected for adjustment. Never start work on any pipes if you are unsure of their function and never touch gas supply pipes. Always make sure that the water supply is isolated and pipe drained before beginning work.

|

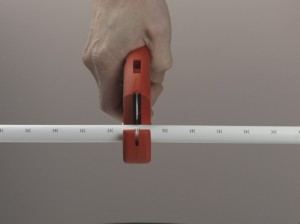

1. The best tool for cutting plastic pipe is a purpose made plastic pipe cutter. This has a razor sharp blade that makes a precise, square cut through the pipe. |

|

2. Position a pipe insert in each end of the pipes you want to join. These stop the pipe ends from distorting when you make the joint. |

|

3. Push the pipes into the joint as far as they will go. The markings on the side of the pipes help you gauge how far the pipe needs to be inserted. |

|

4. To lock the joint you may need to twist each side of the joint in opposing directions. This further improves the seal. |

|

5. If adjustment is required, to disassemble the joint, twist to unlock and apply pressure on the grab-ring collar with one hand while pulling the pipe out with the other. |

Push-fit plastic joint tips

- Above is shown 15mm plastic pipe. The other common size in domestic situations is 22mm – therefore make sure you get the right size joints when you buy. Also, a straight coupler is shown here, but the principles of joining remain the same for other shapes and designs of joint.

- Plastic joints may generally be used to join copper pipe as well, but check the manufacturer’s guidelines.

- Some designs of plastic joint will also need a de-mounting tool if you need to take the joint apart for adjustment.

- For more about plastic push-fit joints, see my guide – ‘Plumbing joints’.

I came across your site while searching for more information about my mower, but I always love a great do-it-yourself site. I’m going to bookmark the site and look forward to reading more articles.